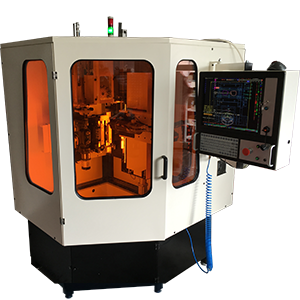

MF5 front machine

The OAXA MF5 machine is an automatic 5 axis machine which enables all manufacturing steps on acetate spectacle fronts.

Operation is automatic, and does not require supervision.

5 axis milling

The OAXA MF5 machine features simultaneous 5 axis milling characteristics which are currently unrivaled :

Milling intricacy: Thanks to the Lona4 software, based on “downstream process” and specifically designed for use in the eyewear industry, users have an unequaled creative potential within complex 5 axis manufacturing, which is unrivaled today.

Surface shape condition: OAXA MF5 machine produces the best surface finish of 5 axis manufacturing currently available on the market.

Precise

CNC machining offers an accuracy of + or – 0.02 mm with a perfect surface finish.

Flexible

The programming of the MF5 is made simple thanks to the Lona4 software based on “downstream process” an OAXA innovation.

The machining as well as the extensibles, the centering eye shape and even the bending tools are rapidly and automatically generated from the model.

The changeover of the front model is very fast.

Automatic

The OAXA MF5 machine is fully automatic: material loading, machining, finishing, turnover of the spectacle front, hinge housings, and ejection of the finished frame.

The machine is designed to operate unattended

Top of the range technical characteristics

High-quality brushless motor, fast feed of up to 15 m / mn

HF spindle with automatic tool changeover (10 tools), liquid cooling, frequency converter for

an adjustable rotation speed of 5 to 24000rpm.

Linear guides: Three pre-stressed ball pads per linear axis. Permissible static load: 1350 dN per skid, dynamic load: 833 dN: these are very high quality machine tool components.

Rotary axes: innovative high performance gearboxes with excellent repetition accuracy.

Precision ball screws with two pre-stressed ball nuts. Load capacity per ball nut: 700 dN

Material magazine: 1200 mm (200 pieces 6 mm thick). It is possible to load plates with glued cleats/rectangle of a thickness of up to 19mm.

CNC programming using the Lona4 software: machining is automatically generated from the design without prior machining definition or software change. The model file is copied from the design station into the machine using a USB key

Size of the machine: 1200x1200x1800 – Weight: 700kg

Power supply: electric: 380 V triphase (220V US standard optional). Dry air 7 bars.

To manufacture top of the range frames

Width of up to 80 mm

Maximum thickness: 3 to 10 mm (or 19 mm with glued rectangles)

Max. Length: 100 to 210 mm

Manufacturing capacity: depends on the complexity of the model. Up to 50 pieces / hour

Repetition accuracy: 0.02 mm

Max. Tool number: 10 with an automatic tool change over and adjustable speed from 5 to 24000 rpm

Integrated design software: yes

Training, delivery, start-up: yes

Standards and safety

✔ Complies with Electromagnetic Compatibility Directive 89/336 / EEC (EMC) and 92/31 / EEC and EN 55011

✔ Connection to a standard electrical networks whose voltages comply with international standard IEC 60 038

Prices