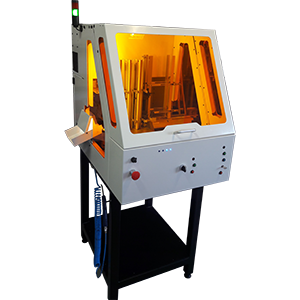

MC1 welding machine

OAXA MC1 machine is a friction welding machine which is fully automatic and very simple to operate.

Friction welding

Friction welding enables a perfect welding of the acetate plates. The welding is performed using an exclusive OAXA friction frequency, precisely adapted to acetate of cellulose, which the approach is the result of innovative research and development.

The weld is entirely invisible even after polishing. The homogeneity of the material is preserved, there are no bubbles, additional products or deterioration of the materials. The quality of the finished parts is without compromises.

Productivity Features

The machine is fully automated which allows for unattended operation.

It features an “Adjustable” plate loader adaptable to all dimensions.

The rectangle loader is adjustable. It allows for up to 3 rectangles to be glued simultaneously : the nose pad and two sides.

High production rate. The welding cycle takes between 15 and 25 seconds which give s the OAXA MC1 machine a respectable production capacity of 180 pieces per hour.

Ease of implementation

Very straight forward to learn how to use.

No consumables (acetone)

No tooling required regardless of the size or thickness of the plates

The welded parts can be machined immediately after the gluing cycle

The only tooling required depends on the size and position of the rectangles which are specific to each client.

A tool is delivered with the machine and the clients can do the tooling themselves if required.

Technical characteristics

✔ 500 mm chip loader: ~ 80 plates with an example thickness of 6

Possibility to refill the loader while the machine is in operation

✔ Size of the plates: width 30 to 80 mm, length 100 to 200 mm, thickness 3 to 10 mm

✔ Three rectangle loaders of 500 mm: ~ 125 rectangles with an example thickness 4mm, per loader. Possibility of refilling the loaders while the machine is in operation.

✔ Dimension of the rectangles: 15×15 to 50x30mm. Thickness: 3 to 16 mm

✔ Thickness of the plate + the rectangle after welding: up to 19mm

✔ Loss of thickness after welding: <0.4mm (total thickness after welding = plate thickness + rectangle thickness – 0.4mm)

✔ Maximum weldable surface: the maximum weldable surface without the risk of a bubble forming is approximately 40x40mm.

✔ Possibility of welding two superimposed rectangles (optional)

✔ Option to glue plates edge to edge: no

✔ No difference in the quality between 2 welded plates and one single unit.

✔ Noise: 65Db

✔ Training, delivery, start-up.

Standards and safety

✔ Complies with Directive 2006/42 / EC and 2004/108 / EC (Machine Directive)

✔ Complies with Electromagnetic Compatibility Directive 89/336 / EEC (EMC) and 92/31 / EEC and EN 55011

✔ Connection to a standard electrical network whose voltages comply with international standards IEC 60 038

Price

40 000 €